Premium Sluice Gate Valves for Optimal Control

Dependable End-of-Line Design

Sluice Gate Valves feature a robust cast iron slide, are engineered for superior performance and durability, and ensure efficient water control.

Operation is simple: open by rotating counterclockwise and close by turning clockwise. The design includes adjustable bronze wedges for enhanced sealing, ensuring reliable closure. Maintenance is minimal, requiring only regular visual checks and occasional lubrication, making these valves a practical choice for busy industries.

Installation is streamlined and compatible with standard 125-lb. flanges, reflecting Troy Valve's commitment to versatile, user-friendly designs. As a trusted sluice gate valve manufacturer, we also provide comprehensive parts availability and expert support, ensuring our valves meet your needs reliably and efficiently.

Standard Features

As opposed to fabricated parts, our cast parts have less potential for failure over time.

Our unique assembly doesn’t require rails to guide the disc, allowing for easy installation.

With an unseating pressure rating of 50 psi, our sluice gates perform better than the industry standard.

Our sluice gates can be easily operated by using an extension stem with 2” nut and socket, floor stand or hand wheel.

Our sluice gates are constructed with a stainless steel stem to prevent corrosion and ensure smooth operation.

For our larger models (12”), special ball bearing adjustment screws help to ensure a fully even positive seal.

Cast Stainless Steel Sluice Gates

Penn-Troy currently offers 4” sluice gates with a cast stainless steel construction.

Sluice Gate Operators

Find all the operator options and accessories you need for opening and closing your sluice gate.

Sluice Gate Operators

Find all the operator options and accessories you need for opening and closing your sluice gate.

Learn More

Operation

The sluice gate is a non-rising stem type. The gate is opened by rotating the operating mechanism in a counter clockwise (open left) direction. The gate is closed by rotating the operating mechanism in a clockwise direction.

The operation mechanism may be a 2” square nut attached directly to the operating stem of the valve, a 2” square nut attached to the valve operating stem by an extension stem and coupling, or hand wheel attached to the valve operating stem by an extension stem and coupling.

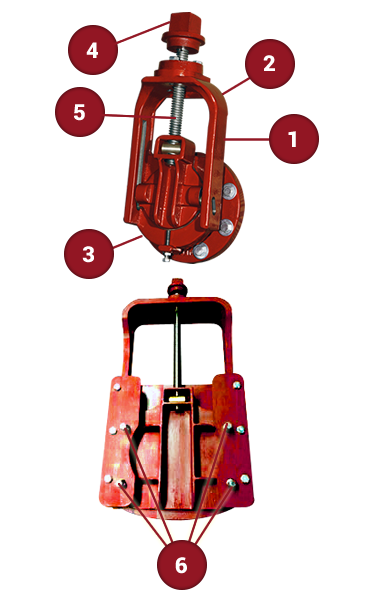

The disc seat is forced against the seat in the body by a wedging action. The wedging action is created by two (2) adjustable bronze wedges mounted on the gate disc and the cast iron guide mounted to the gate body. See Drawing A-3500, items (6) and (3).

Maintenance

Visual inspection of the bronze seats and wedges are recommended when the gate is accessible. Gate operation should be observed to ensure the gate is opening and closing evenly against the wedges. Adjust bronze wedges as necessary to correct wedging action. Lubricate stem and stem nut each time maintenance is performed.

Installation

The gate flange is drilled to the 125-lb. standard template for mounting on flanged pipe drilled and typed for studs. Flange holes straddle the vertical centerline.

Parts

Parts are available by request. Please contact us for more information. Troy Valve is one the world's most reliable sluice gates manufacturers.

You Have A Problem. We Have The Solution.

Confidence